When it comes to managing waste and recycling, there are many important factors that must be taken into account. Arguably, the most important criterion for success is reliable data. For years, the waste industry depended largely upon estimated quantities and capacities, and the data that was available lacked accuracy and sometimes even relevance. However, in a changing industry, technology continues to provide opportunities for change and disruption. One of the most innovative pieces of technology that we have seen revolutionize waste in the past several years is the implementation of sensors.

Sensors provide management companies and clients with the opportunity to track real time data on their waste capacity with precision, providing an evidence-based approach to designing and managing waste and recycling programs. Management companies like Waste Solutions offer sensor technology to maximize the quality of their service offerings and improve transparency. This technology allows us to monitor container fullness, ensure the most efficient pick-up schedule, track waste hauler performance and optimize the customer experience.

Types of Sensors

-

Ultrasonic Sensors

Ultrasonic sensors are electronic devices that emit ultrasonic sound waves to detect distance and space. When placed in a waste bin, these sensors are able to detect the fullness or remaining capacity of the container. Ultrasonic waste sensors utilize machine learning and artificial intelligence to identify when waste needs to be collected.

Using ultrasonic waves or “beams,” these sensors track fill levels of most types of waste, allowing customers and suppliers alike to monitor the true capacity demands of the waste program, and thus maximize efficiencies. Generally, ultrasonic sensors are most effective when used in front end load bins, or dumpsters.

-

Image Based Sensors

Similarly, to ultrasonic sensors, image-based sensors are able to measure the fullness and remaining capacity of a waste or recycling container. However, rather than using ultrasonic technology, they utilize a wide-angle camera lens to capture real time photos which are sent to a cloud for monitoring and further analytics.

The client or management company can access these photos to monitor the fill level of the bin, and also take note of any other potential concerns such as illegal dumping, contamination in recycling bins, and more. Clients benefit from the accuracy and timed / dated information provided by these photos, and management companies are able to maximize service levels and container sizing using this data. Image based sensors can be used in front end load containers and is the only option currently available for roll-off bins.

Service Optimization

When launching a sensor program there are a few key goals. Ideally, a management company will monitor the sensor data in order to support the client in reducing costs, improving their environmental impact, and to maximize service efficiencies (most notably regarding scheduling).

Dynamic Scheduling

Launching a sensor program allows management companies and clients to work together to implement a service schedule that reflects the true needs of the client. This means servicing containers only when it is needed and eliminating unnecessary lifts when a bin is not at capacity. The aim is to maximize the capacity of waste containers, ensure correct sizing, and develop a dynamic servicing schedule that meets the needs of the location.

Control Costs

By monitoring bin fullness levels, unneeded services can be eliminated, thus cutting out the cost of unnecessary service. Anticipating haul schedules gives management companies the opportunity to ensure service meets the needs of the client without ‘over-servicing.’ This information is also able to be used to verify bin sizing, ensuring the right size containers are in place, resolving capacity issues that can increase costs. This can be particularly valuable in industries where waste generation may not be consistent on a day-to-day basis, or when setting up a new client.

Environmental Impact

By eliminating unnecessary service, you are also eliminating unnecessary trucks on the road. The environmental impact of reducing waste truck routes to only service when truly needed will reduce greenhouse gases (most notably the carbon footprint), and thus minimize the environmental impact for the service location. This data will also benefit management companies as they work to design their routes, giving them the opportunity to route their collection trucks effectively, without making unnecessary detours to lift bins that have remaining capacity / volume in them.

Operational improvements

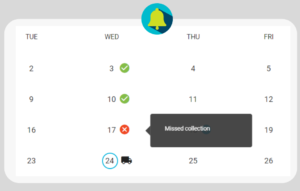

Managing Missed Service

If a service has been missed, frustration from all parties can ensue if a resolution is not quickly implemented. Sensor technology minimizes this, by providing real-time evidence of missed service (via photographic images or capacity reports), eliminating confusion or miscommunication between the service provider and the client. Sensors also provide an opportunity to identify missed service as quickly as possible, thus allowing the ability to implement a solution without further delay.

Proactive Management of Capacity Levels

Proactive Management of Capacity Levels

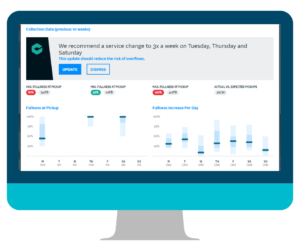

When a container is reaching capacity, the first thing that we want to do as a management company is eliminate the risk of overflow. Overflow poses a health and safety risk and is unsightly for the client. By utilizing sensor technology, we can identify when this is a potential risk, and schedule service accordingly in order to stop it in its tracks. Further, we are then able to monitor the bin going forward to identify if this is an ongoing capacity issue where scheduling should be adjusted, or if it was a one-time occurrence.

Better Data

Better Data

Knowledge is power, and in the waste industry this comes in the form of data. Sensor technology allows us to dive deep and gather real time data about our clients’ programs and use that information to maximize service efficiencies and improve the customer experience for our clients.

Traditional Hauler Data

Traditionally, haulers have used estimates instead of evidence-based systems when reporting volume and capacity data to clients. These estimates have been based upon bin sizes, industry standards, and weights. In most cases the estimated weights provided to customers by haulers is based on a percentage of the truck load and not your actual containers. The truth is, variations within any given waste stream can be extreme, and estimates are not an accurate way to measure the volume of a bin, or the capacity needs of any client. Sensor technology has revolutionized this approach, allowing us to provide clients with true data regarding their programs and capacities.

Modern Data

Launching a sensor program enables us to report on actual fill levels with actual data. Sensor technology brings the waste industry into the 21st century, leaving behind traditional estimation methods and allowing us to manage waste and recycling programs with an evidence-based approach. Not only can this modern approach to waste data be used to improve service efficiencies, but its accuracy is also dependable enough that it can be used for diversion and carbon impact reporting. Sensor technology can turn any container into a smart device, revolutionizing the way that we manage waste.

Revolutionizing The Way We Manage Waste

Sensor technology provide us with the opportunity to turn any waste bin into a smart device, disrupting the waste industry and modernizing the way we manage waste. In a changing industry, sensor technology enables us to provide next level service for our clients.

If your location is experiencing service issues, or you are unsure if your containers are being filled efficiently, sensor technology could be the answer to your problems. The Waste Solutions team is happy to work with our clients to optimize their programs utilizing the newest technologies, setting the standard for service industry wide.