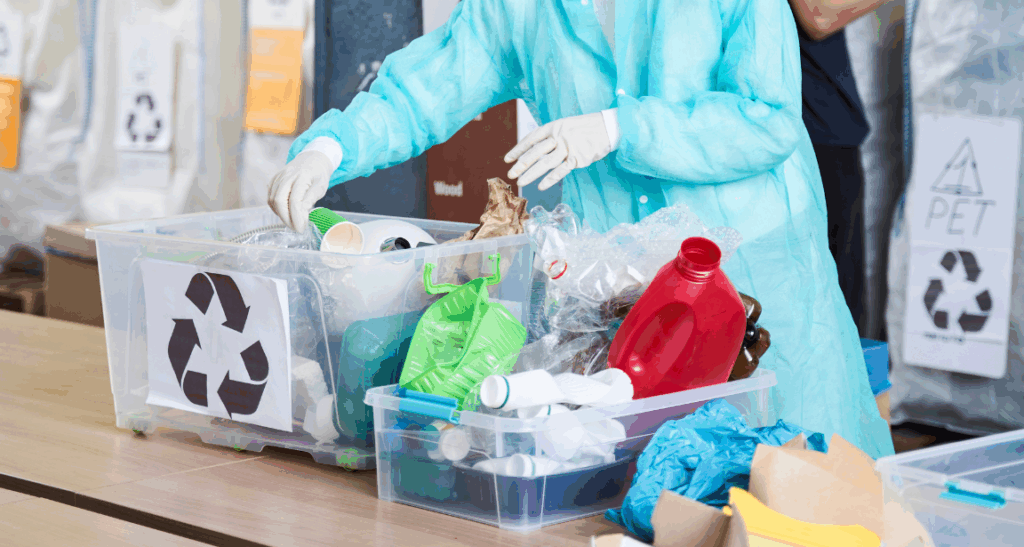

Waste audits play a crucial role in providing businesses with valuable insights into their waste generation patterns and composition, offering a pathway to identify cost reduction opportunities and enhance operational efficiency. By conducting thorough waste audits, organizations can uncover areas for improvement in waste management practices, procurement processes, and resource utilization. This proactive approach not only leads to immediate cost savings but also sets the foundation for long-term sustainability and competitive advantage in the marketplace.

The Financial Benefits of Waste Audits for Businesses

Waste audits offer businesses valuable insights into waste generation patterns and composition, presenting numerous opportunities for cost reduction and operational efficiency improvements.

Waste Disposal Fees Reduction

One of the most immediate and measurable benefits of a waste audit is the potential to lower your waste disposal costs. When businesses identify ways to reduce the volume of waste sent to landfill — through recycling, composting, or reuse — they often see a direct reduction in disposal fees. Since many waste service contracts are volume-based, even small changes in waste diversion can have a big impact on your bottom line.

Unlock Procurement Cost Savings

Waste audits also shed light on what’s being discarded — and why. By analyzing the types and quantities of materials thrown away, businesses can identify inefficiencies like:

-

Excess packaging

-

Single-use or disposable items

-

Over-ordering or spoilage

This data can support changes in purchasing strategies, such as using recycled materials or switching to more sustainable suppliers. These changes often result in both cost reductions and improved environmental outcomes.

Generate Revenue from Recycling Programs

In addition to cost savings, waste audits can uncover revenue-generating opportunities through recycling initiatives. Many recyclable materials, such as paper, cardboard, plastics, metals, and glass, have market value when sold to recycling facilities. By separating valuable materials from the general waste stream and partnering with local recyclers, businesses can create a new income source while reducing landfill costs.

Operational and Environmental Efficiency Gains

Efficient waste management practices foster operational efficiency improvements across various aspects of business operations. By streamlining waste handling processes, implementing waste reduction strategies, and optimizing resource utilization, businesses can minimize downtime, reduce labour costs, and enhance overall productivity. Furthermore, a focus on waste reduction and recycling can promote a culture of sustainability within the organization, leading to increased employee engagement, morale, and retention.

Avoid Long-Term Costs and Regulatory Risks

Investing in waste audits and implementing sustainable waste management practices not only yields immediate cost savings but also results in long-term cost avoidance.  By proactively addressing waste generation and disposal issues, businesses mitigate the risk of future regulatory non-compliance penalties, potential environmental liabilities, and reputational damage. Moreover, reducing dependency on finite resources and transitioning to a circular economy model through waste reduction and recycling initiatives can safeguard businesses against future price volatility and supply chain disruptions associated with resource scarcity.

By proactively addressing waste generation and disposal issues, businesses mitigate the risk of future regulatory non-compliance penalties, potential environmental liabilities, and reputational damage. Moreover, reducing dependency on finite resources and transitioning to a circular economy model through waste reduction and recycling initiatives can safeguard businesses against future price volatility and supply chain disruptions associated with resource scarcity.

Boost Resource Efficiency Across Your Organization

Efficient use of resources is paramount for sustainable business operations. Waste audits enable businesses to pinpoint inefficiencies in resource utilization and identify areas for improvement. By optimizing resource usage and minimizing waste generation, organizations can enhance their operational efficiency and productivity.

Efficient use of resources is paramount for sustainable business operations. Waste audits enable businesses to pinpoint inefficiencies in resource utilization and identify areas for improvement. By optimizing resource usage and minimizing waste generation, organizations can enhance their operational efficiency and productivity.

Identifying Resource Waste

A comprehensive waste audit gives businesses a clear view of how materials, energy, and water are used — and wasted. This includes:

-

Overuse of paper or plastic

-

Excess food waste

-

Inefficient use of energy or water

Once resource waste is identified, it becomes easier to implement targeted improvements that reduce both environmental impact and operational costs.

Streamline Processes and Embrace Circular Practices

Insights gained from waste audits can inform process improvements aimed at reducing resource waste throughout the production cycle. By analyzing production workflows and material flows, businesses can identify opportunities to streamline processes, minimize material losses, and eliminate bottlenecks. For example, businesses may reconfigure production layouts to minimize material handling and transportation distances, implement lean manufacturing principles to reduce excess inventory and waste, or invest in technologies that improve resource efficiency, such as energy-efficient equipment and recycling systems.

Insights gained from waste audits can inform process improvements aimed at reducing resource waste throughout the production cycle. By analyzing production workflows and material flows, businesses can identify opportunities to streamline processes, minimize material losses, and eliminate bottlenecks. For example, businesses may reconfigure production layouts to minimize material handling and transportation distances, implement lean manufacturing principles to reduce excess inventory and waste, or invest in technologies that improve resource efficiency, such as energy-efficient equipment and recycling systems.

Implementing Waste Reduction Measures

Based on the findings of waste audits, businesses can implement waste reduction measures to minimize resource waste at the source.  This may involve redesigning products and packaging to optimize material use, substituting virgin materials with recycled or renewable alternatives, or adopting circular economy principles that prioritize resource recovery and reuse. By incorporating waste reduction strategies into product design, procurement practices, and operational procedures, businesses can minimize resource waste while maximizing resource value throughout the product lifecycle.

This may involve redesigning products and packaging to optimize material use, substituting virgin materials with recycled or renewable alternatives, or adopting circular economy principles that prioritize resource recovery and reuse. By incorporating waste reduction strategies into product design, procurement practices, and operational procedures, businesses can minimize resource waste while maximizing resource value throughout the product lifecycle.

Optimizing Supply Chain Management

Waste audits extend beyond the boundaries of individual businesses to encompass the entire supply chain. By collaborating with suppliers, distributors, and other partners, businesses can identify opportunities to reduce resource waste and improve efficiency across the supply chain.  This may include sourcing materials from environmentally responsible suppliers, implementing just-in-time inventory systems to minimize excess inventory and waste, and establishing reverse logistics processes to recover and recycle materials at the end of their useful life. By optimizing supply chain management practices, businesses can enhance resource efficiency while reducing costs and environmental impact.

This may include sourcing materials from environmentally responsible suppliers, implementing just-in-time inventory systems to minimize excess inventory and waste, and establishing reverse logistics processes to recover and recycle materials at the end of their useful life. By optimizing supply chain management practices, businesses can enhance resource efficiency while reducing costs and environmental impact.

Monitoring and Continuous Improvement

Waste audits serve as a valuable tool for monitoring resource efficiency performance over time and identifying opportunities for continuous improvement. By establishing key performance indicators (KPIs) related to resource usage, waste generation, and recycling rates, businesses can track their progress toward resource efficiency goals and benchmark their performance against industry standards. Regular monitoring and analysis of waste audit data enable businesses to identify trends, detect inefficiencies, and implement corrective actions to optimize resource efficiency and minimize waste generation continually.

Conclusion

In conclusion, waste audits are powerful tools that enable businesses to reduce costs, increase revenue, and enhance operational efficiency through strategic waste management practices. By leveraging the insights gained from waste audits, organizations can optimize resource utilization, streamline production processes, implement waste reduction measures, and foster collaboration across the supply chain. By embracing a culture of sustainability and continuous improvement, businesses can not only minimize waste generation and disposal but also drive long-term cost avoidance, mitigate risks, and strengthen their resilience in the face of evolving market dynamics. Through a commitment to resource efficiency and waste reduction, businesses can pave the way for a more sustainable and profitable future.

If you’re interested in streamlining your waste management processes and making a positive impact, contact our team of waste audit experts today!